CNCTOPBAOS 4 Axis CNC Controller DDCSV4.1,PLC Offline Stand Alone System Replace Mach3,Slave Stepper Servo Motor Motion Controller for CNC Router Engraving Lathe Milling Machine

$329.00

Price: $329.00

(as of Aug 12, 2024 14:07:54 UTC – Details)

Product Description

4 Axis DDCSV4.1 Offline Standalone Motion Controller

Product packaging:

1 × 4 Axis DDCSV4.1 CNC offline stand alone motion controller1 × 4GB USB flash drive1 × USB extension cable and other small accessories1 × parallel port link cable1 × Breakout BoardPdf. user manual (If you have not received the user manual at Amazon Message Center from us,please message us)

Introduction

The DDCS V4.1 4 axis motion controller for stepper and servo system, is updated from DDCS V3.1 on software and hardware. It combines great advancement with tiny footprint of each days from past 8 years. The DDCS numerical control system adopts the ARM + FPGA design framework. ARM controls the human-computer interface and G-code analysis and the FPGA provides the underlying algorithms and creates the control pulse. This ensure reliable control and easy operation. The internal operating system is Linux based.The panel layout structure of the DDCS V4.1 is very rational to save space. All operations are controlled by only 17 keys and the keys are composite keys that can act as function keys or numeric keys. DDCS V4.1 support comprehensive Fanuc G code set. The DDCS can be used for many styles and types of CNC machines. Lathes, Routers, Pick&Place and Mills are just a few examples. The DDCS operates as a Stand Alone system without the need of a computer. This ensure high precision, accuracy and reliability. The interface, even though very comprehensive, can be learned in a very short time.

DDCSV4.1 Brief technical features

1) 18 photoelectric isolated digital inputs,3 photoelectric isolated digital outputs.

2) The spindle can be set as Analog spindle(0~10V) and also Servo spindle.

3) 3-4 axes motor Control. Difffferential Mode and Double Pulse Mode output signal for optional, Maximum interpolation pulse output frequency is 500Khz/Axis, 2-4 Axis linear interpolation, any 2 axis circular interpolation;

4) ARM9 main control chip,FPGA core algorithm chip.

5) 7 inches TFT screen, Size: 1024×600 Pixels, Resolution:72 Pixels/Inch; 17 operation keys.

6) The Power Supply for IO Port is 24VDC,minimum current is 0.5A, the Power Supply for Control ler system is also 24VDC,minimum current is 0.5A. Controller needs both power to work properly.

7) USB flflash disk support for G code fifile input; Can transfer the fifiles by Ethernet communication between the computer and DDCS V4.1 controller; No size limited of the G-code fifile.

8) Compatible with standard G-code, support popular CAD/CAM software, such as ArtCam, MasterCam, ProE, JDSoft SurfMill, Aspire, Fusion 360 and so on;

9) Support standard MPG.

10) Support function of“ Try cutting” (handwheel guiding) function. the distance.

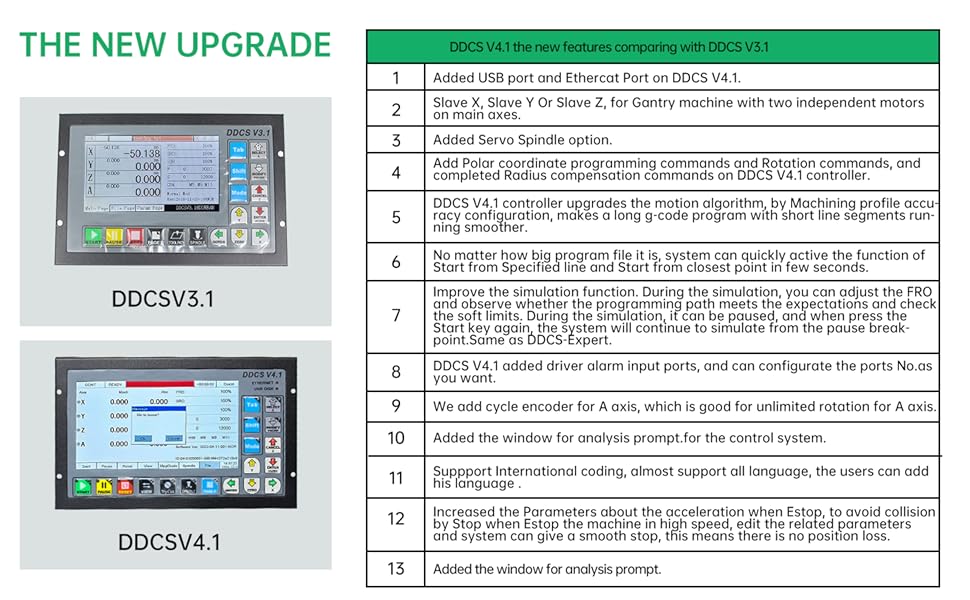

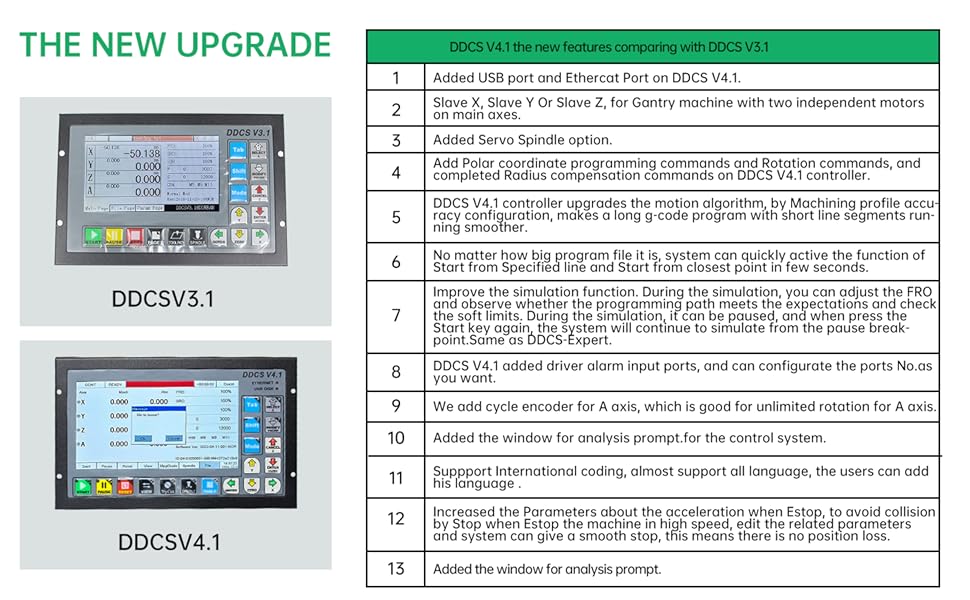

DDCS V4.1 the new features comparing with DDCS V3.1

More functions

11)Support Jog function for each axis (continuous, step, defifined distance), Customer can defifine

12)Support Float Probe, Fix Probe, Vertex Probe and Tool Length Measurement.

13) Support the operation of quickly go to specify line and closest position. cal machining.

14) Support Array Machining, Sequence Machining, Milling Plane Machining, and Milling sylindri-

15) Support Bias for XYZA axis, and can defifind the Bias distance.

16) Support Pause breakpoint, Power-Cut Recovery Beakpoint and loaded breakpoint; And Support Start from the specifific line and closest line.

17) Support Multiple origin points operation, the users can create an origin point and load it.

18) Support Find Middle for X and Y axis.

19) Improved the simulation function. During the simulation, you can adjust the FRO and observe whether the programming path meets the expectations and check the soft limits. During the simulation, it can be paused, and when press the Start key again, the system will continue to simulate from the pause breakpoint.

20) Slave X, Slave Y Or Slave Z, for Gantry machine with two independent motors on main axes.

21) Now English and Chinese language is avaliable; System also suppport International coding, almost support all language, the users can add their own language to the control system.

22) DDCS V4.1 Only Supports NPN Type Limited Switch.

23) Support 4 kinds operation rights: visitor, operator, admin, super admin.

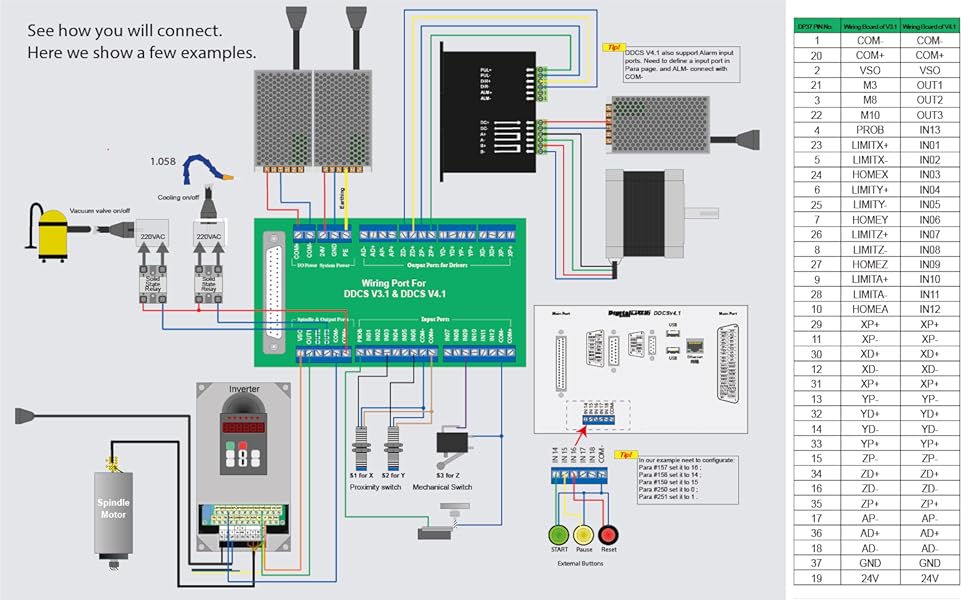

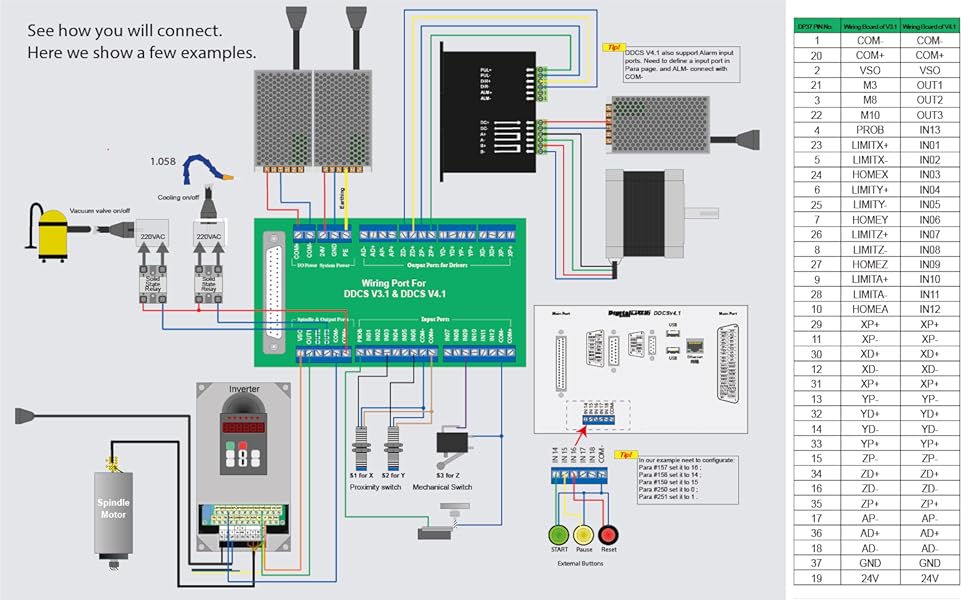

Needs two power supplies

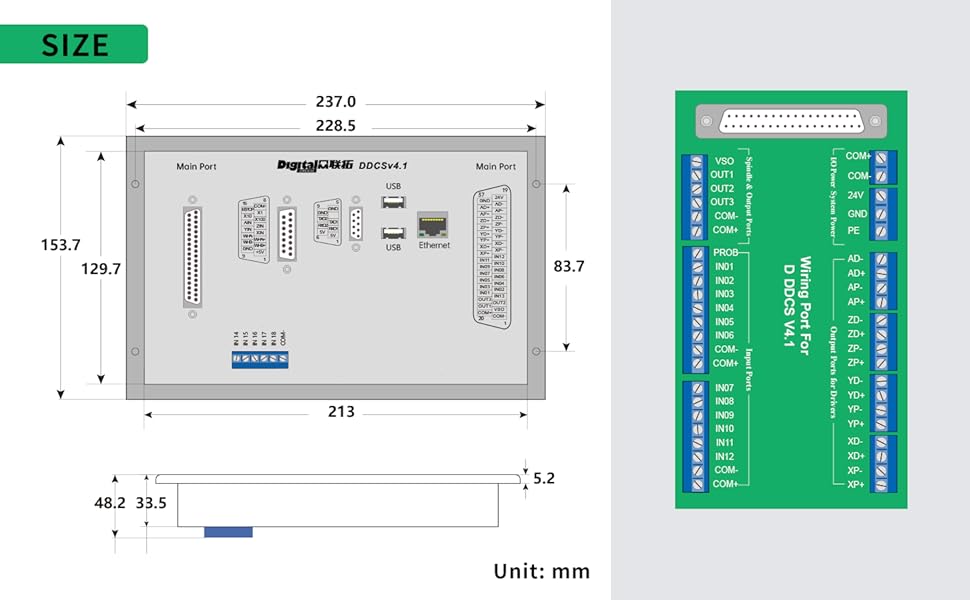

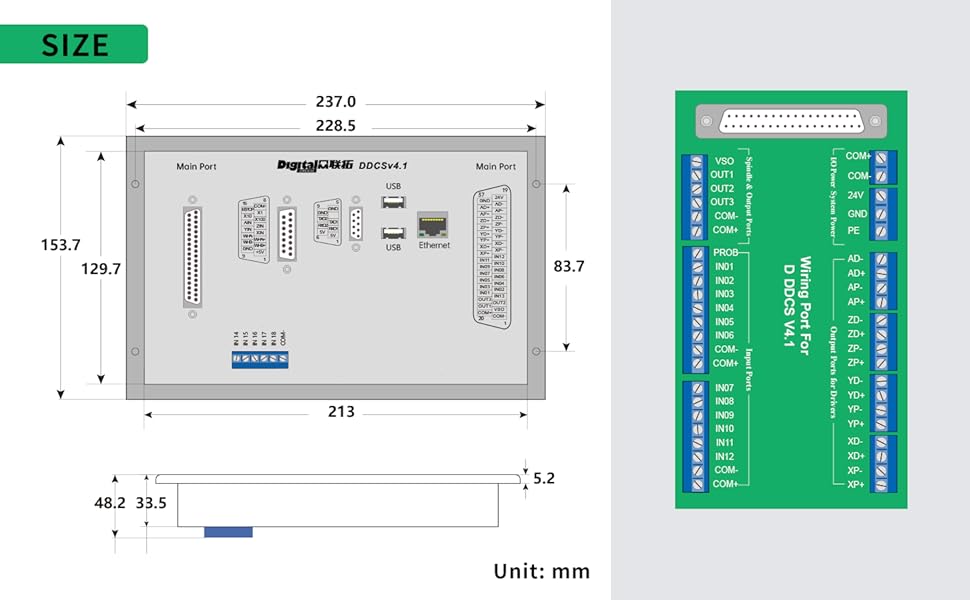

COM+ and COM- is the power input ports for Input/Output Port and MPG, 24V and GND is the power input ports for controller system. Please keep in mind,only when the two power supplies are connected correctly the controller can be work properly.The DDCS V4.1 is a small box that can fit in a window of a small control box or control cabinet. Four locking hooks fix this controller from the frame. The dimension you find in Figure 1-3.The front panel is 237mm * 153.7mm * 5.2mm;The main body is 237mm * 153.7mm * 48.2mm;To mount the unit in an equipment cabinet, cut the hole 228.5mm * 83.7mm

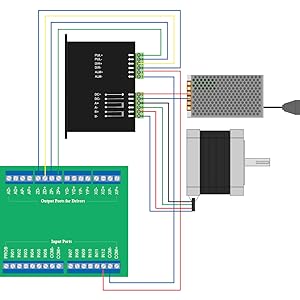

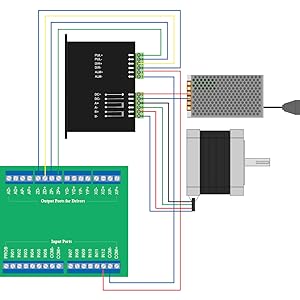

DDCS V4.1 Stepper/Servo Control Output

The stepper/servo control output,we cite differential Pulse and Direction output method.By the Para #012~015, the users can configurate the drive mode for the 4 axis.

Max. output frequency is 500Khz, please take attention to the max. pluse input frequency of the driver.

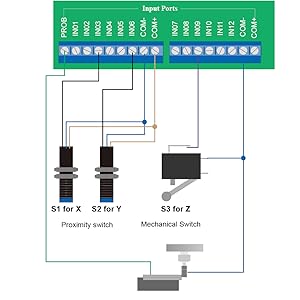

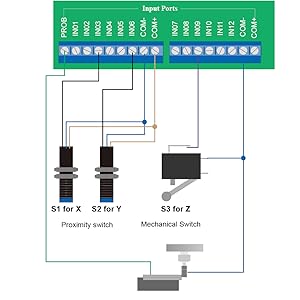

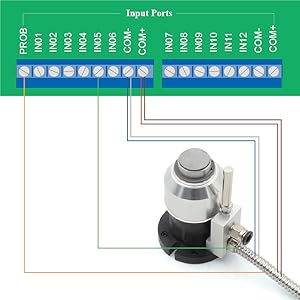

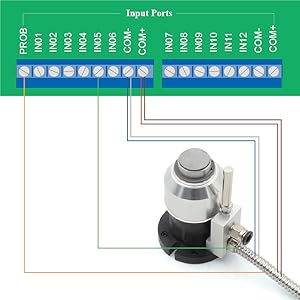

Limit, Home and Probe Inputs

The digital input circuit has the mechanical limit switch connection method and the open collector of the triode connection method. It supports the NPN type proximity limit switch.The example above, we already set at Submenu “Input signal Para” in the Parameters page as:#151: X axis Home port is 03, then IN03 is the X axir home signal input port;#152: Y axis Home port is 06, then IN06 is the Y axir home signal input port;#153: Z axis Home port is 09, then IN09 is the Y axir home signal input port.#156: Probe Port is 13, then IN13 is the probe signal input port.

Extended Function Inputs

#250~#253 Extended function key functions: 0 “Start”; 1 “Pause”; 2 “XY Zero”; 3 “Z Zero”; 4 “Home”; 5 “Floatting probe”; 6 “Fixing probe”; 7 “Vertex probe”; 8 “X 1/2”; 9 “Y 1/2; 10 “extkey1.nc”; 11 “Disable”. The users can select the function as they want.Take the example, how to defind the “Start”, “Pause” and “E-stop”Extended function to the external keys.By Submenu “Input signal Parameters” in the Parameters page:Set “#157 External emergency stop port” to No. 16 input port; Set “#158 Extended Function Key 1 Port” to No. 14 input port; “#159 Extended Function Key 1 Port” to No. 15 input port.Then set #250 to 0, then define input port 14 as “Start”; Set # 251 to 1, to defind the input port 15 as the “Pause”.The users also can edit Macro to self-define the external key function by “extkey.nc“. The appendix also includes a list of macro definitions.

DDCSV4.1 Spindle control outputs

DDCS V4.1 Support 2 kinds Spindle Mode: Analog Spindle / Servo Spindle (PUL+DIR). By Para #188 configurate the spindle as Analog or Servo Spindle, By Para #189 we select the servo spindle channel. Here we take the example of the analog spindle.The spindle control output ports (OUT01-OUT03) offer connections for Start and Stop of the Spindle (M3/M5), Start/Stop of Cooling (M8/M9), Start/Stop of Lubrication (M10/M11). These three output terminals are signals open to ground. The highest electric current can be absorbed is 50mA. The speed controlling output terminal can output 0-10V. It can adjust the speed of the spindle motor by sending the voltage between 0 and 10V to the VFD according the the Spindle Speed Setting.The above Figure shows the wiring with Sunfar VFD.

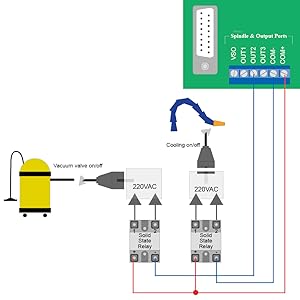

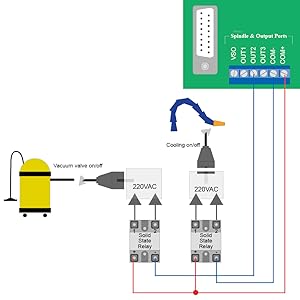

DDCSV4.1 output ports wiring with relay

OUT0-OUT3 can be used as General comman output ports, for example, can be used as the solid relay output ports, take the example of the figure above.After Wiring, in the View page, we can check the wiring situation.The related Parameter settings:In the Parameter Page, the Sub-menu “Output signal Para”, we can configurate the output number of M3/M5, M8/M9, M10/M11 and the electrical level.In the Parameter Page, the Sub-menu “M output code Para”, we can set the delay time of M3/M4,M8/M9 and M10/M11.

Probe Input ports

We configurate the IN13 as the Probe signal input port, and IN05 as the Z– hard limit signal input port. Then wiring as above.After completing the wiring, we can check the input ports status at the View page.In the Sub-menu “Home Para” of the Paramters page, we can set the Home direction of each axis, the Home Speed, the back-distance and so on. And comparing with DDCS V3.1, the 4.1 version controller added the coordinate setting of the 4 references points.

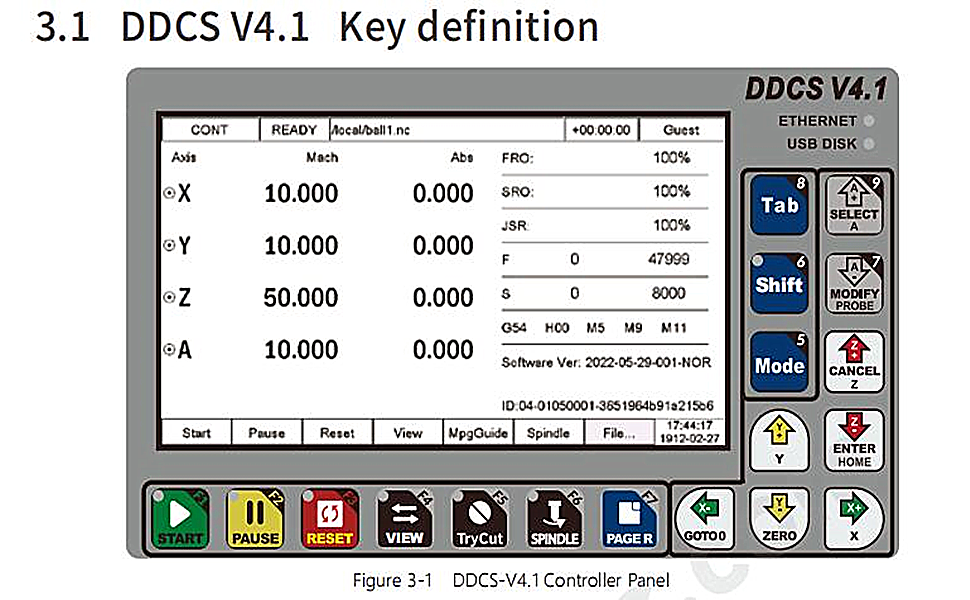

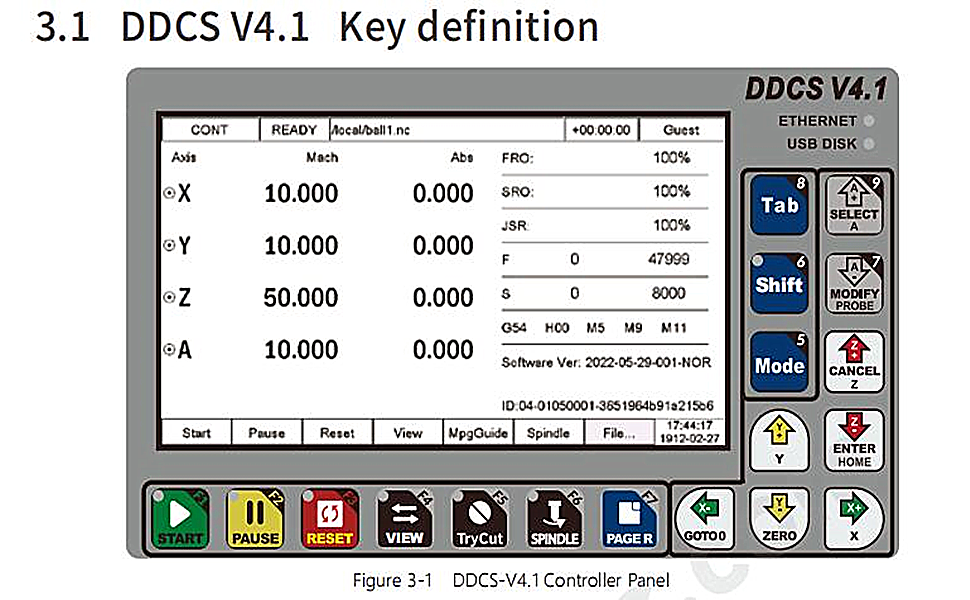

DDCS V4.1 Key definition

“Shift” key can be defined as “Menu” or “2nd function” by parameter #313, among which the menu function is the newly added content of DDCS V4.1.It should be noted that since DDCS V4.1 has correspondingly added many functions, only 17 keys is really not enough, so we defined the “Start” and other keys totally 7 keys to be composite keys, and at the same time, namely F1-F7, which can be Perform corresponding operations accord ing to the on-screen prompts.This column shows the mechanical coordinate value of each axis,the display range is -99999.999~+99999.999,the precision is 0.001;Please note the current unit is in metric or imperial.The default is metric,we can edit it in Parameter #001.

♞【Model Number】DDCS V4.1 ; 7 inches TFT screen, resolution ratio: 1024×600 ,17 operation keys;Difffferential Mode and Double Pulse Mode output signal for optional, Maximum interpolation pulse output frequency is 500Khz/Axis, 2-4 Axis linear interpolation, any 2 axis circular interpolation;

♞【Feature】ARM9 main control chip,FPGA core algorithm chip;18 photoelectric isolated digital inputs,3 photoelectric isolated digital outputs. The spindle can be confifigurated as Analog spindle(0~10V) and also Servo spindle.

♞【Slave function】Slave X, Slave Y Or Slave Z, for Gantry machine with two independent motors on main axes;

♞【Power requirements】The Power Supply for IO Port is 24VDC,minimum current is 0.5A, the Power Supply for Control ler system is also 24VDC,minimum current is 0.5A. Controller needs both power to work properly.

♞【Support G code file】USB flash disk support for G code file input; Can transfer the files by Ethernet communication between the computer and DDCS V4.1 controller; No size limited of the G-code file.

User Reviews

Be the first to review “CNCTOPBAOS 4 Axis CNC Controller DDCSV4.1,PLC Offline Stand Alone System Replace Mach3,Slave Stepper Servo Motor Motion Controller for CNC Router Engraving Lathe Milling Machine”

$329.00

There are no reviews yet.